Quick Details:

VMC-2015 metal CNC machine center

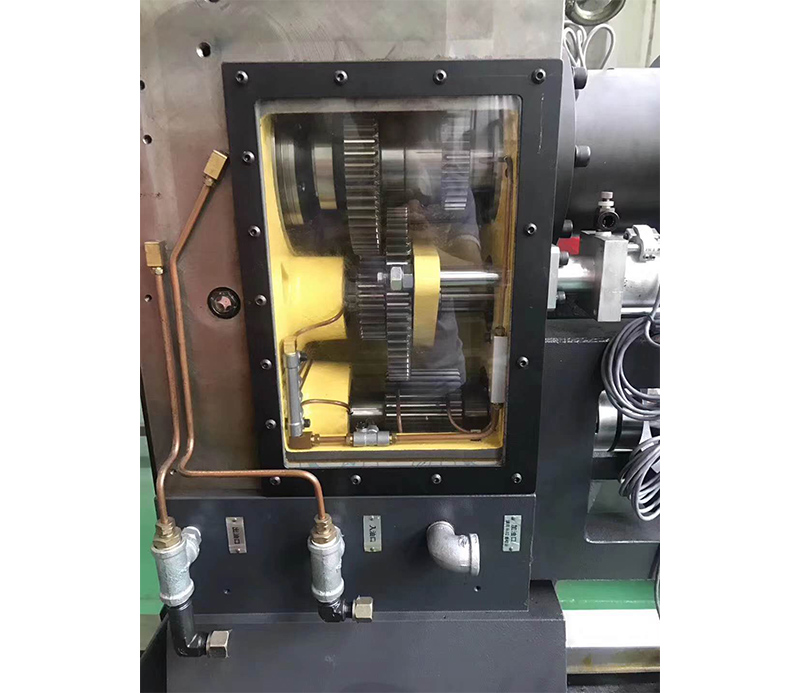

The machine tool adopts bbt50 spindle originated in Taiwan. It can also be equipped with internal gear box spindle. It is suitable for heavy cutting with low speed and high torque, and high-speed finish machining. It is most suitable for multi task sequential machining of parts, such as milling, drilling, Gong, hinge, tapping, two-dimensional and three-dimensional curved surfaces. The internal gear spindle box has large input-output speed ratio, good gear cooling effect, and easy control of rough It is also particularly suitable for mold base processing, and is widely used in mold base, automobile, internal combustion engine, aerospace, household appliances, general machinery and other industries.

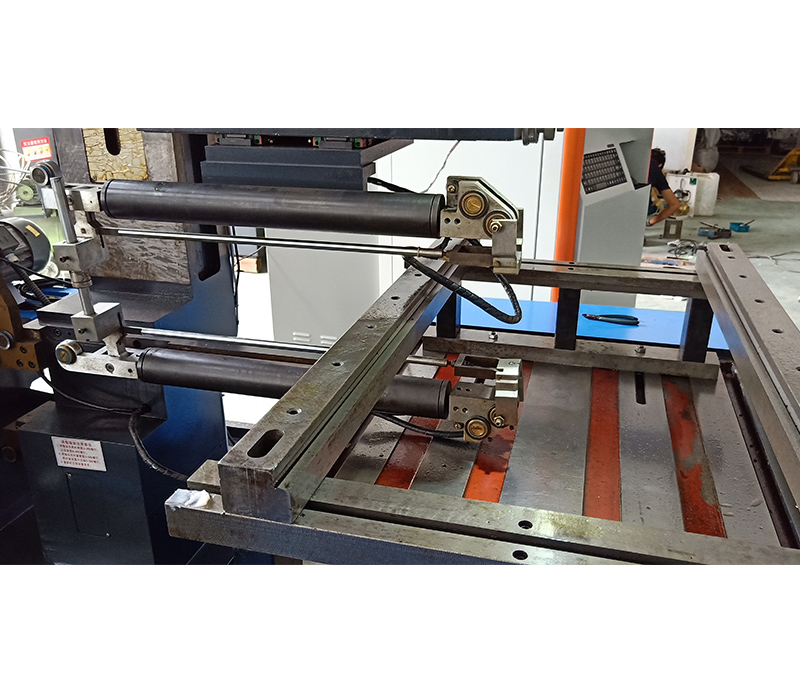

1.X. Y and Z axes adopt high rigid roller track, which can prevent sliding delay, reduce wear and increase the long-term accuracy retention of the machine tool.

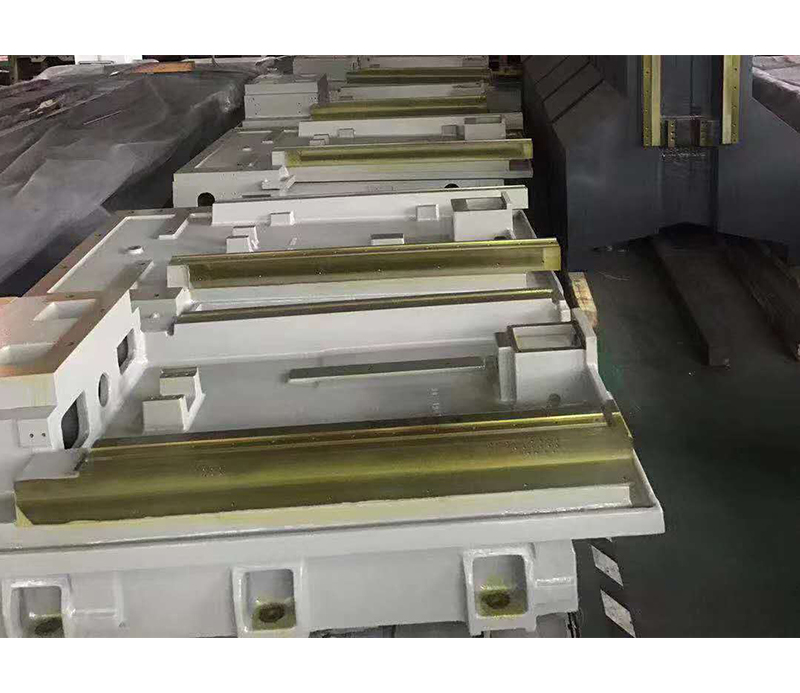

2.The machine bed, column, worktable, spindle box and other large parts are made of high-quality resin sand modeling, high-strength and high-quality fc-30 high-grade cast iron. The stress is eliminated by tempering, and the reinforcing ribs are arranged inside the machine bed, so that the machine bed structure is heavy and heavy, so that the machine tool can obtain high rigidity and long-term stable accuracy.

3.X. Y and Z axes adopt imported large-diameter lead screws with compact structure, stable movement and high precision. They are combined into an impeccable mechanical transmission system with high rigidity and high stability. Pre tension is applied at both ends to eliminate the precision loss caused by thermal elongation.

Model | VMC-2015 |

X-axis Travel mm | 2000 |

Y-axis Travel mm | 1500 |

Z-axis Travel mm | 750 |

Spindle end to table mm | 170-920 |

Spindle speed rpm | 4000/6000 |

Spindle motor power kw | 25 |

Three axis motor power kw | X7/Y4.5/Z4.5 |

Table area mm | 1200*2100 |

T-groove (groove * width * center distance) mm | 7-22*150 |

X-axis rapid displacement mm/min | 12000 |

Y-axis rapid displacement mm/min | 12000 |

Z-axis rapid displacement mm/min | 12000 |

feed rate mm/min | 1-5000 |

Spindle taper | BT50 |

Prop quantity | 40 |

Maximum tool diameter mm | 240 |

Maximum tool length mm | 305 |

Tool weight kg | 150 |

Tool magazine category | Disc type |

Air pressure source kg/cm² | 8 |

Bearing of worktable kg | 3500 |

Machine tool weight kg | 26000 |