Quick Details:

VMC-4025 3 Axis CNC Line Rail Vertical Machining Center

On the basis of inheriting the advantages of strong rigidity, symmetrical structure and strong stability of the foundation frame of the traditional vertical machining center, the machine tool introduces the international advanced dynamic rigidity design concept and optimizes the design of moving parts. The machine tool has large torque and good fast response characteristics. High speed, strong and stable cutting, high-precision machining of inner hole, outer circle, chamfer, groove, thread and various arc surfaces, which is suitable for the needs of various machining fields such as automobile, mold, aviation, aerospace, military industry, hardware and so on.

1. Spindle head

The contact length ratio between the main shaft and the column is appropriate to provide stable support for the main shaft. An independent cooling system is built in the spindle head to continuously stabilize the heat of the spindle head within a reasonable range, reduce the thermal extension of the spindle and ensure the machining accuracy.

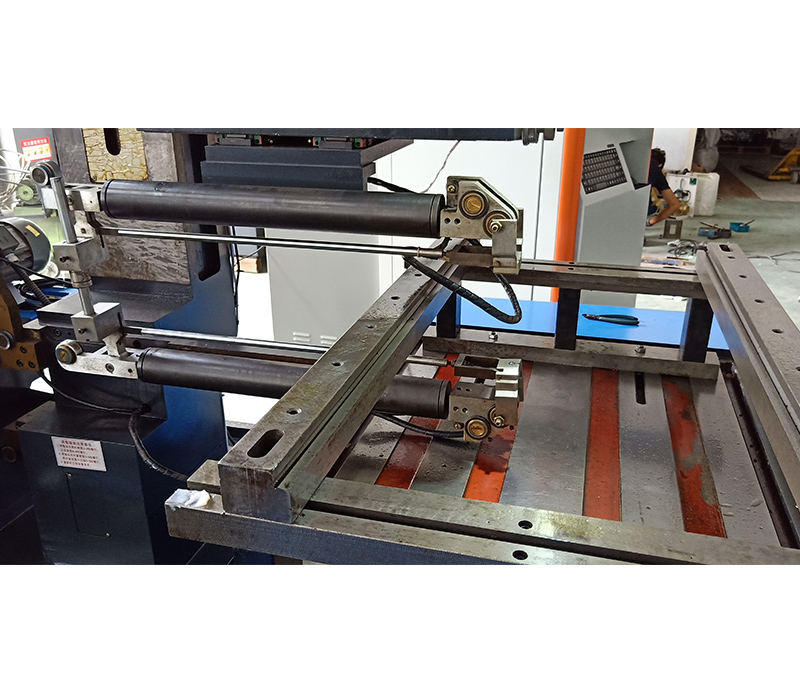

2.Screw rod

The imported grinding grade pre pulled double nut screw rod is adopted to eliminate the reverse gap. After heat treatment, it has high rigidity, wear resistance, torque resistance and long service life, which ensures the high machining accuracy of the machine.

3. Lubrication system

The whole machine adopts positive displacement lubrication system and pressure relief oil pump, which has stable pressure and flow, effectively transmits the oil to each lubrication point, and provides uniform forced lubrication on each slide surface to ensure the accuracy and service life of the machine tool.

Model | VMC-4025 |

X-axis Travel mm | 4000 |

Y-axis Travel mm | 2500 |

Z-axis Travel mm | 1000 |

Spindle end to table mm | 150-1150 |

Spindle speed rpm | 4000/6000 |

Spindle motor power kw | 25 |

Three axis motor power kw | X7/Y4.5/Z4.5 |

Table area mm | 2200*4600 |

T-groove (groove * width * center distance) mm | 11-28*200 |

X-axis rapid displacement mm/min | 10000 |

Y-axis rapid displacement mm/min | 10000 |

Z-axis rapid displacement mm/min | 10000 |

feed rate mm/min | 1-5000 |

Spindle taper | BT50 |

Prop quantity | 60 |

Maximum tool diameter mm | 300 |

Maximum tool length mm | 315 |

Tool weight kg | 25 |

Tool magazine category | Disc type |

Air pressure source kg/cm² | 10 |

Bearing of worktable kg | 5500 |

Machine tool weight kg | 46000 |