Quick Details:

VMC-1690 high speed CNC machine center

High speed CNC machine center is applicable to the vertical machining center in the field of machining and mold manufacturing. It can meet the machining requirements from rough machining to finish machining, and can complete a variety of processes such as milling, drilling, tapping and boring.

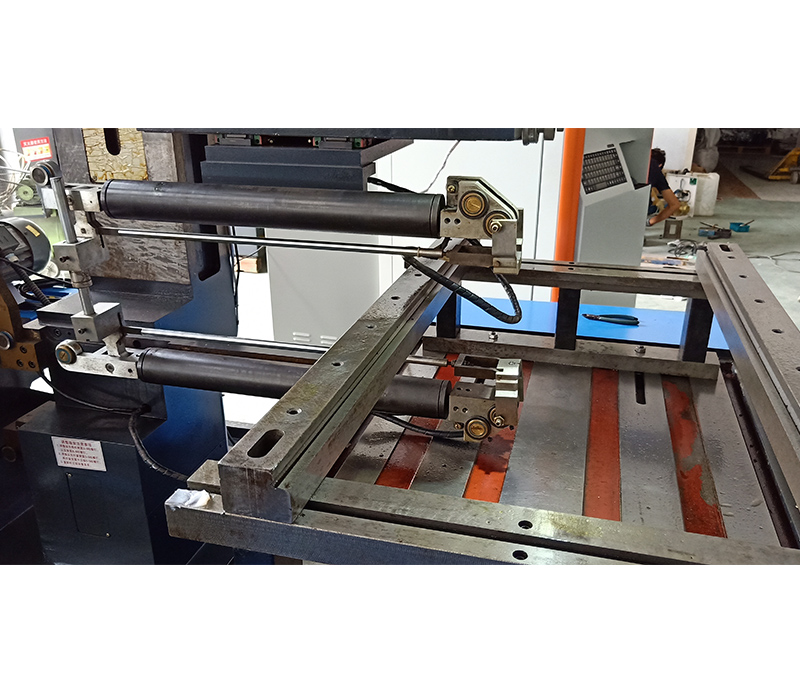

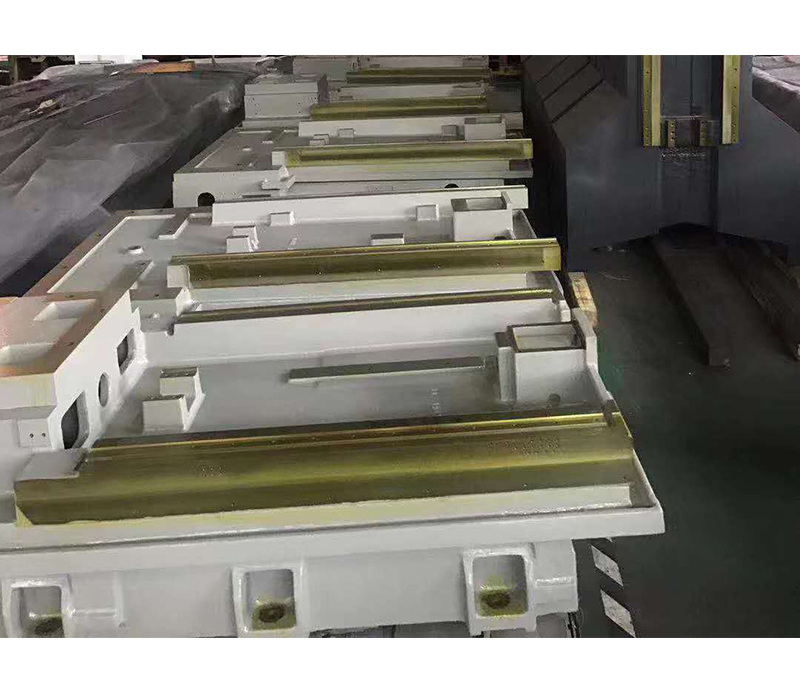

The vertical machining center adopts the vertical frame layout, the column is fixed on the bed, the spindle box moves up and down along the column (z direction), the sliding seat moves longitudinally along the bed (Y direction), and the worktable moves laterally along the sliding seat (x direction). Large parts such as bed, worktable, sliding seat, column and spindle box are made of high-strength cast iron, shaped by resin sand process, and stress is eliminated by twice aging treatment. These large parts are optimized by SW and ANSYS to improve the stiffness and stability of large parts and the whole machine, and effectively suppress the deformation and vibration of the machine tool caused by cutting force.

Model | VMC-1690 |

X-axis Travel mm | 1500 |

Y-axis Travel mm | 800 |

Z-axis Travel mm | 700 |

Spindle end to table mm | / |

Spindle speed rpm | 8000 |

Spindle motor power kw | 15 |

Three axis motor power kw | X4.5/Y4.5/Z4.5 |

Table area mm | 1700*800 |

T-groove (groove * width * center distance) mm | 5-22x1400 |

X-axis rapid displacement mm/min | 16000 |

Y-axis rapid displacement mm/min | 16000 |

Z-axis rapid displacement mm/min | 16000 |

feed rate mm/min | 12000 |

Spindle taper | BT50 |

Prop quantity | |

Maximum tool diameter mm | 150 |

Maximum tool length mm | 305 |

Tool weight kg | 10 |

Tool magazine category | Disc type |

Air pressure source kg/cm² | 6 |

Bearing of worktable kg | 800 |

Machine tool weight kg | 12000 |