Quick Details:

VMC-1160V Drill Linear Rail Vertical Machining Center

Drill Linear Rail Vertical Machining Center can complete drilling, milling, boring, expanding, reaming, tapping and other processes for various complex parts such as plates, plates, shells and molds in one clamping. It is suitable for parts processing in automobile parts, electrical instruments, motorcycles, tools, hardware, electrical machinery and other industries. It can be used for efficient processing and manufacturing of small and medium-sized batch parts, showing its advantages for the processing of complex and high-precision parts, and can also form an automatic production line for vertical machining center.

1.The overall structure is made of high toughness and high-grade cast iron, and after efficient annealing heat treatment, it can effectively eliminate the internal stress of the material and ensure the best accuracy, stability and durability.

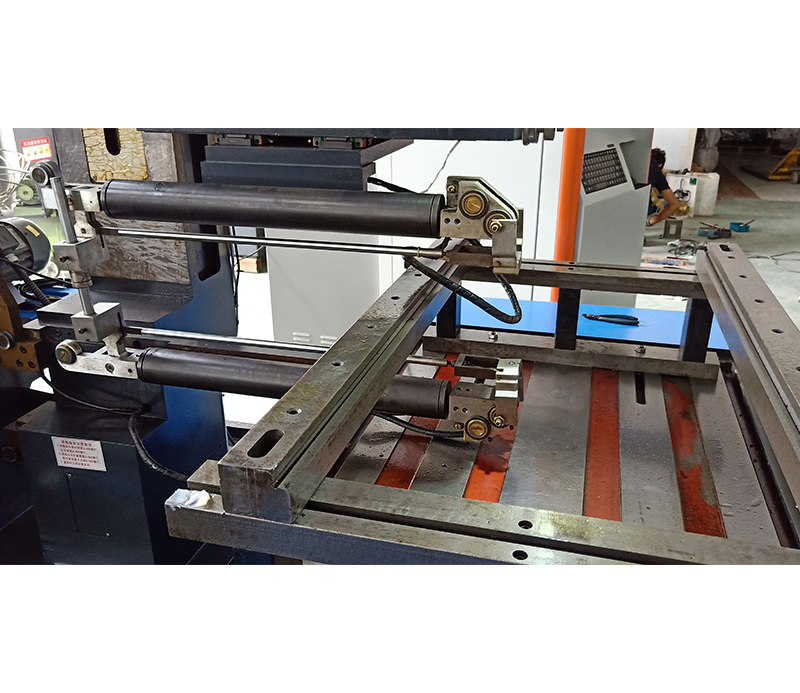

2.The Y-axis of the base is a structural design of two track linear rails, with a linear gauge of 850mm. The support column on the track surface has good stability and rigidity, and has good quality for general processing mold manufacturing.

3.The counterweight system is equipped with a heavy block track to obtain support when the main shaft head moves up and down, effectively control the poor machining problems caused by vibration and ensure stable accuracy.

4.The column is designed with large "herringbone" shape and large span, with high rigidity and stability. It is matched and connected with the solid and stable base, which shows the accuracy and accuracy of the processed parts and can meet the perfect requirements.

5.Whip seat and worktable adopt double compartment design, which can reduce vibration during processing and ensure processing accuracy.

Model | VMC-1160V |

X-axis Travel mm | 1100 |

Y-axis Travel mm | 600 |

Z-axis Travel mm | 600 |

Spindle end to table mm | 70-670 |

Spindle speed rpm | 12000 |

Spindle motor power kw | 11 |

Three axis motor power kw | X3/Y3/Z3 |

Table area mm | 600*1300 |

T-groove (groove * width * center distance) mm | 3-18-150 |

X-axis rapid displacement mm/min | 36000 |

Y-axis rapid displacement mm/min | 36000 |

Z-axis rapid displacement mm/min | 36000 |

feed rate mm/min | 12000 |

Spindle taper | BT40 |

Prop quantity | |

Maximum tool diameter mm | 150 |

Maximum tool length mm | 305 |

Tool weight kg | 7 |

Tool magazine category | Bamboo hat / knife arm |

Air pressure source kg/cm² | 6 |

Bearing of worktable kg | 800 |

Machine tool weight kg | 7000 |