Quick Details:

DK77100 High Efficiency Fast Wire Cutting

High efficiency fast wire cutting is a set of machine tool electrical appliances, high frequency power supply, servo control and graphics programming as one, to achieve high efficiency, high precision, high finish, simple processing control, greatly improve the processing level of fast wire cutting machine. Flexible commutation with frequency converter is adopted in machine tool commutation, which can arbitrarily adjust the speed of wire conveyor drum, thereby improving the smoothness of workpiece. High efficiency (cutting efficiency can reach 7000 to 8000 square millimeters per hour) is twice the cutting efficiency of ordinary machine tools. Energy saving (machine energy consumption is 0.85 degrees per hour) is 50% more energy saving than that of ordinary machine tools. Environmental protection (machine tool environmental protection water cover to prevent working fluid splashing) can be replaced once in 30 working days by using high-pressure filter water tank working fluid, which greatly improves working time and reduces the number of sewage discharge. The electrical parts of the machine tool are all installed in the control cabinet for waterproof treatment, and all the oil supply is integrated with manual oil pump.

1.Select paired clearance-free bearings to improve accuracy.

2. Selection of high quality ball screw

3. Using steel-inlaid guide rail

4. Good assembly process requirements

5.By using frequency converter, the speed of the wire drum can be adjusted arbitrarily, thus improving the smoothness of the workpiece.

6.Conventional processing efficiency can reach 150 mm2/min.

| project | parameters |

| Model | Dk77100; fast wire |

| Electrical cabinet form | Stepping type of vertical cabinet |

| Guide | V flat guide rail |

| Lead screw form | Ball screw |

| XY motion motor form | Stepper motor |

| Working mode of wire conveying motor | Frequency converter speed regulation 1 ~ 12m / S |

| Machine tool protection | Environmental protection cover |

| Resolution of motion axis | 0.001mm |

| Table size | 1150X1600 |

| X. Y axial stroke | 1000X1200mm |

| U. V-axis stroke | ±35×±35mm |

| Machining taper / machining thickness | ±6°/80mm |

| Maximum straight cutting thickness | 1100mm(Z-axis electric lifting) |

| control mode | 4 axis linkage |

| Maximum load capacity | 1500kg |

| Maximum processing current | 8A |

| Maximum processing efficiency Cr12, H = 60mm | ≥180 mm²/m |

| Surface roughness (straight cutting, H ≤ 40mm) | Ra≤2.5μm |

| Cutting accuracy Cr12, H = 40mm | ≤0.015mm |

| Radial runout of wire storage cylinder | ≤0.02mm |

| Molybdenum wire diameter range | 0.12~0.22mm |

| Wire storage capacity of wire storage cylinder | 250m |

| Molybdenum wire loss Cr12, H = 40mm | ≤0.02mm /300000mm², |

| Cutting power supply | High frequency power supply system without resistance |

| operating system | Windows 98/XP (According to the control software) |

| Control system | StandardAUTOCUT |

| communication interface | LAN、RS232、USB |

| Operation function | Drawing or CAD drawing import |

| Working tank volume | 55L |

| Working fluid filtration mode | Filter screen filtration |

| Weight of whole machine | 6000 kg |

| Overall dimension of main engine | 2500x2300x2500mm |

| Cabinet size | 730×630×1820mm |

| Rated power of electric appliance | ≤ 2.7kW |

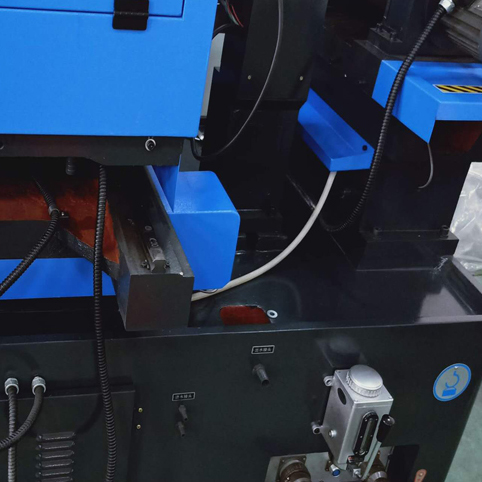

sample pictures