Quick Details:

1. Main performance characteristics of machine tools

1. Adaptive electrical discharge machining control

2. Timed high-speed knife lifting and knife lifting height control

3. Spindle fixed-point control and discharge gap detection

4. Oil level control

5. Fire prevention control

6. Automatic alarm safety device

7. Anti carbon accumulation function

8. CNC system, touch screen input, manual control box operation.

9. Automatic measurement of work pieces on the machine

10. Fine edge processing

11. Delta servo system for X, Y, and Z axes.

12. Minimum electrode loss 0.10%

13. Optimal surface roughness Ra 0.15μm

14. Maximum production efficiency of 500 mm ³/min

15. Minimum driving unit: 1um

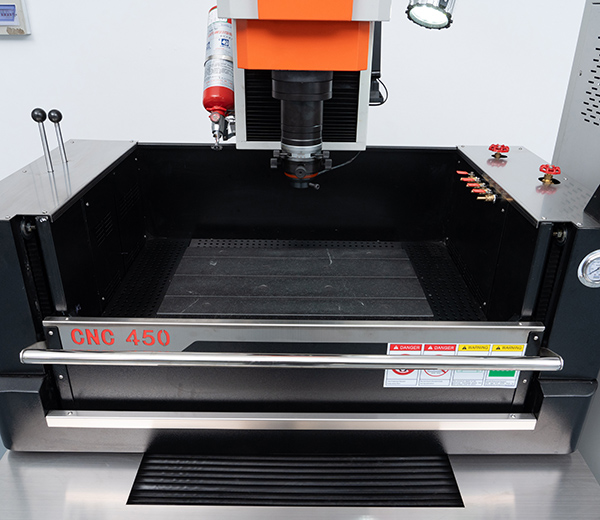

16. Wear resistant edging design for stainless steel materials

2. CNC power supply device

1. 17 inch LCD display.

2. Special processing circuit for hard alloy.

3. AUTO processing function unit.

4. Automatic positioning function unit.

5. High speed and high-precision machining system.

6. Automatic arc clearing circuit unit.

7. Expert Process Database System.

8. CNC instructions, standard G-code, ISO code.

9. Power off reset, error message prompt function.

1. Main technical parameters of machine

Workbench size | 700*400 mm |

X,Y, Z travel | 450*350*300mm |

Internal dimensions of processing liquid tank | 1000*700*450mm |

Maximum electrode weight | 150kg |

Worktable load capacity | 180kg |

Distance from electrode plate to workbench (minimum/maximum) | 150/600 mm |

Total input power | 9KVA |

Input power supply | 380V |

Total weight of the machine kgs | 3200 |

Maximum processing current | 50A |

Control the number of axis | 3-axis 3-linkage |

2. Standard attachments

Machine tool pad iron | 1set |

Hand control box | 1 piece |

Adjustable chuck (standard) | 1 piece |

Machine lamp | 1 piece |

Standard toolbox (tool) | 1 piece |

an instruction manual | 1 set |

Automatic fire extinguishing device | 1 piece |

3. Details of key components in machine

1 | Guide Rail | Hiwin | 2 | Lead ball screw | PMI |

3 | Workbench | Cast iron | 4 | Bearing | NSK |

5 | Three axis AC motor | Delta | 6 | CPU motherboard (industrial control level) | Yanyang |

7 | Fire Extinguisher | Automatic | 8 | Oil pump | Grundfos |

9 | Filter | Filtersun | 10 | Capacitance | HITACHI |

11 | Circuit breaker | LS | 12 | Touch screen | Huiguan |

13 | LCD screen (industrial grade) | SVA | 14 | Switching power supply (industrial grade) | Mean Well |

15 | Contactor | FUJI | 16 | Axial flow fan | Kaku |

17 | Emergency stop | Schneider | 18 | Bridge pile | TOSHIBA,FUJI |